Nov

Everything you need to know about our Coil Heater

Compact Coil Heating Elements: Versatile High-Temperature Solutions

Designed for space-efficient applications, coil heating elements deliver exceptional thermal performance in confined areas, reaching operational temperatures up to 750°C. These heating components combine powerful heat output with a minimal footprint, making them ideal for demanding industrial environments.

Flexible Design Options

Coil heating elements are available in multiple cross-sectional profiles and dimensional specifications. Beyond standard straight and spiral configurations, these heaters can be custom-formed into virtually any geometric pattern to match specific application requirements.

Customizable Heat Distribution

The spacing of coil heaters can be adjusted to meet diverse heating needs. Tightly wound coils generate intensive, localized heat zones, while extended spacing provides uniform heat distribution across broader areas, allowing precise wattage allocation.

Integrated Temperature Monitoring

For enhanced process control, coil heaters can incorporate built-in thermocouple sensors that enable accurate temperature measurement and rapid thermal response. Both J-type and K-type thermocouples are available, with flexible positioning options throughout the coil assembly to optimize temperature sensing locations.

About Coil Heater

Customizable Heat Distribution and Control

These heating elements offer flexible configuration options to match your thermal requirements. When tightly coiled, they deliver high-intensity, focused heat for concentrated heating zones. Alternatively, extended spacing enables even heat distribution across larger surfaces, optimizing power density for your specific application.

Advanced Temperature Monitoring Capabilities

Built-in thermocouple integration provides real-time temperature feedback for superior process control and rapid thermal response.

Compatible with both J-type and K-type thermocouple sensors, these units allow flexible sensor placement at any point along the heating coil, ensuring optimal temperature measurement exactly where you need it.

Key Benefits

- Space-Efficient Performance, Delivers powerful heating capacity in minimal installation space, maximizing your equipment layout

- Cost-Effective Operation, Combines superior thermal efficiency with economical pricing for excellent return on investment

- Accurate Temperature Management, Ensures consistent, precise thermal control for sensitive processes and materials

- Rapid Thermal Response, Quick heat-up and cool-down cycles improve productivity and process efficiency

- Embedded Sensor Technology, Factory-integrated thermocouples eliminate external wiring complexity and installation time

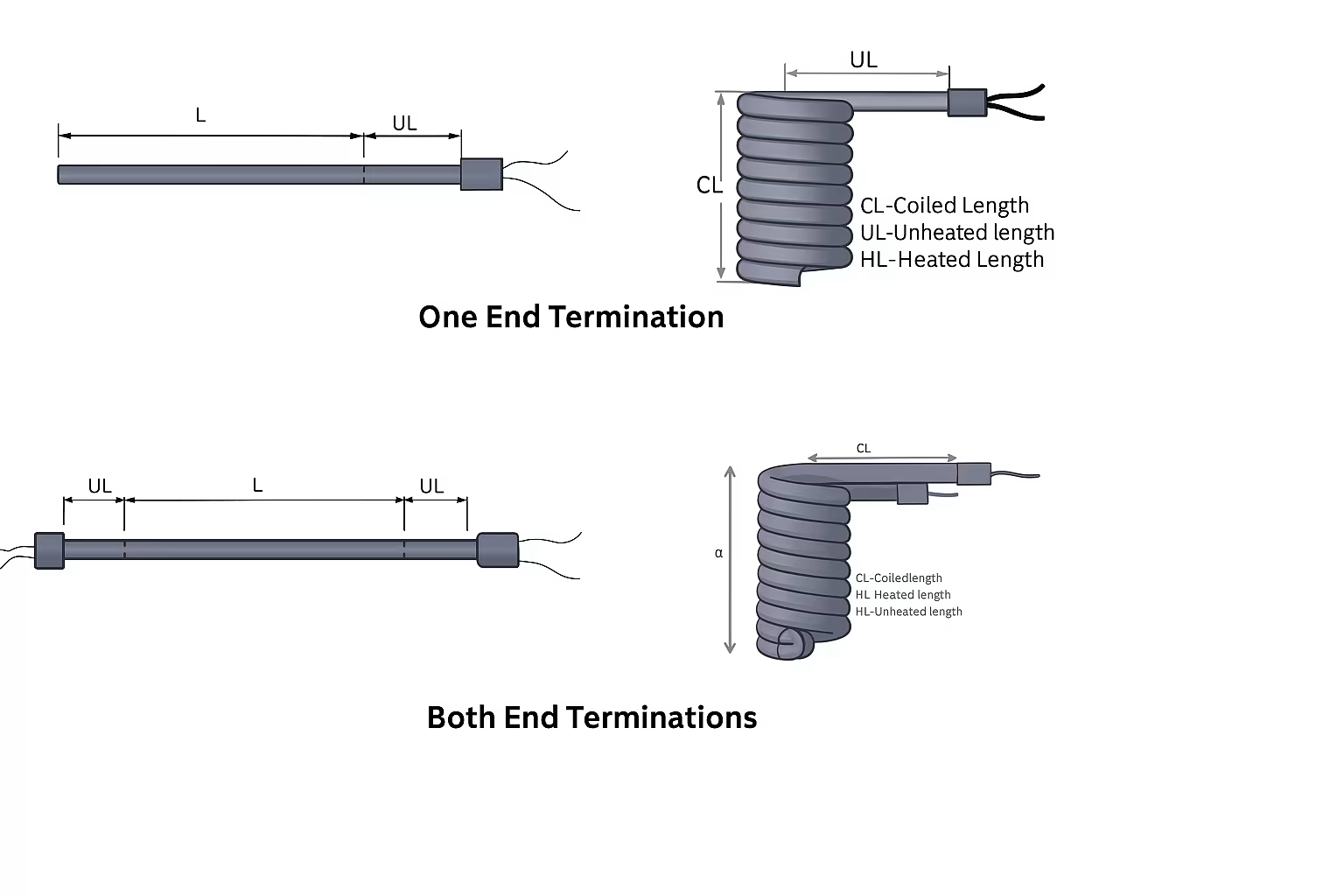

- Versatile Design Options, Multiple coil configurations and termination styles accommodate diverse mounting requirements and spatial constraints

| Sizes | 1.0 x 1.6, 1.3 x 2.3, 1.8 x 3.2, 2.5 x 4.3, 3.4 x 3.4 etc. |

| Sheath Material | Stainless steel / Incoloy |

| Maximum Sheath Temperature | 750°C |

| Maximum Wattage | 200 to 2000 Watts |

| Maximum Voltage | 415V |

| Wattage Tolerance | ± 10% |

| Resistance Tolerance | ± 10% |

| Length Tolerance | ± 5% |

| Minimum Bending Radius | Twice the Sheath Diameter/Width |

| Unheated Zone Length | 10 mm on the bottom end, 50 mm at the terminal end. Larger lengths are available on request. |

Construction

1. Nickel Chromium Resistance wire for maximum life

2. High Purity magnesium oxide fill selected for maximum dielectric strength and thermal conductivity, highly compacted for maximum heat transfer

3. Stainless steel sheath / Inconel sheath for oxidation and corrosion resistance in a wide variety of environments

4. Thermocouple for precise temperature control (type ‘J’ and type ‘K’ thermocouple)

Termination Options

Lead Wire Termination Options

| Wire Type | Temperature Rating | Maximum Recommended Temperature | Comments |

| Ultralead | 250°C | 450°C | Excellent, durable wire, good for high-temperature application |

| Teflon | 250°C | 250°C | Good dielectric strength |

| Silicon Rubber | 200°C | 200°C | Good moisture resistance |

| Braided Silicon rubber | 200°C | 200°C | The inexpensive wire is good for non-abrasive applications. |

| Fibre Glass | 400°C | 400°C | Excellent resistance to heat, flame, abrasion, oil, and chemicals. Excellent dielectric properties. |

Applications

- Zinc Die Casting Machine

- Packaging Machines- Sealing bar and jaws

- Plastics and die casting industries -Machine nozzles

- Hot runner system – Nozzles, Bushings & Distribution plates

- Tube Extrusion

- Pipe Forming

- Small Manifold heating

- Hot Metal forming dies and punches

- Semiconductor manufacturing and wafer processing

📞 Order Your Custom Coil Heater Now!

Don’t waste time searching for a heater that’s “close” to the specifications!

Get the perfect heater – manufactured specifically for your equipment!

Contact Us Today:

Phone/WhatsApp: +974 4411 5256

Email: Info@ekt.qa

Address: Barwa commercial avenue Doha, Qatar